jack ergonomic software

In todays modernized agriculture special-purpose agricultural. Tecnomatix jack offers the possibility of organizing the wor kplace both ergonomically and logistically.

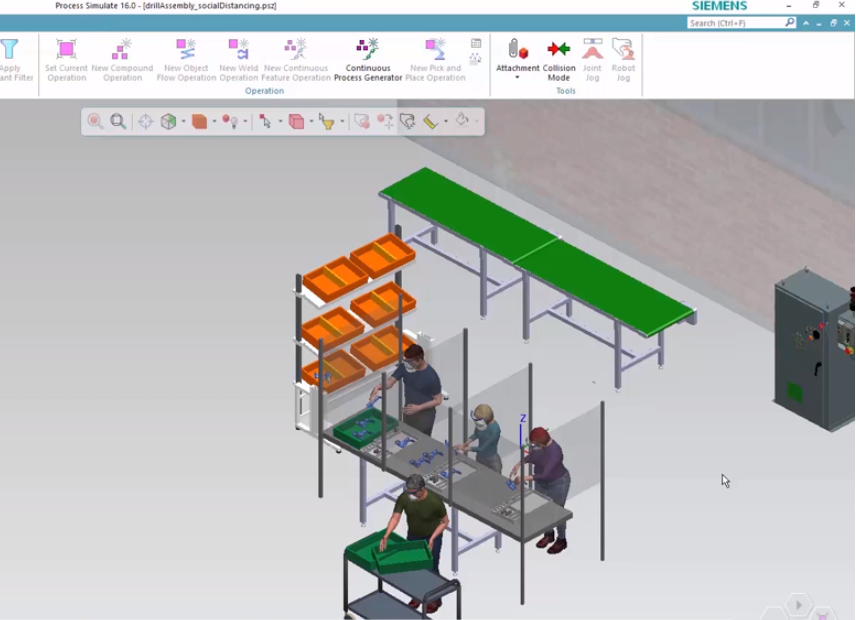

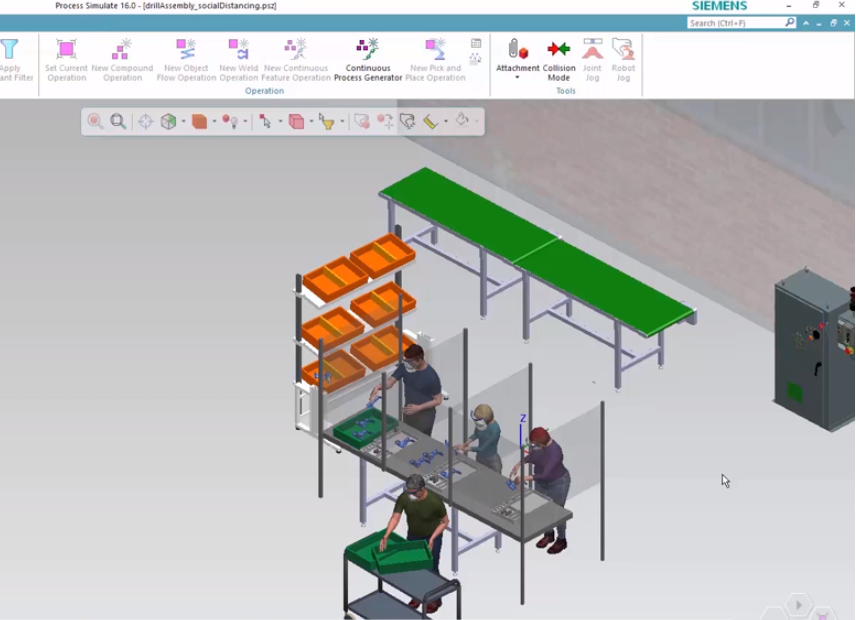

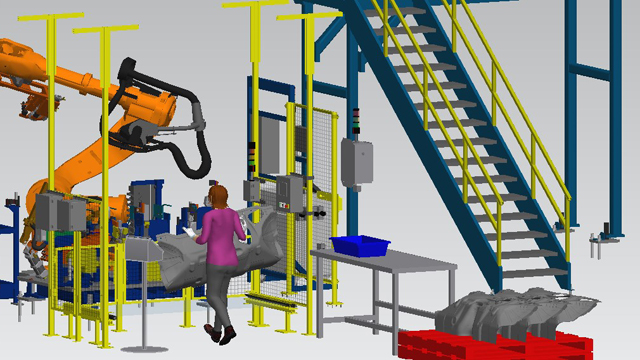

Process Simulate Human provides human-centered design tools for performing ergonomic analysis of virtual products and virtual work environments.

. Motion Builder 3DS Max Maya. AiQ Synertial has created the ultimate communication interface for the Siemens ergonomics software Jack and Process Simulate Human for all AiQ Synertial motion capture systems. Jack and its optional toolkits provides human-centered design tools for performing ergonomic analysis of virtual products and virtual work environments.

Ad The leading ergonomic and compliance platform for hybrid teams and workplaces. Air Force for maintenance simulation and from. The ergonomics of your product designs and to refine industrial tasks.

How to create human body. Tecnomatix Jack is Siemens human simulation and modeling software for ergonomic analysis of human performed tasks in manufacturing facilities. This paper gives the detailed description of the ergonomic weightlifting competition and results.

Youll be able to quickly. Three sets of standing welding a. Jack and its optional toolkits provides human-centered design tools for performing ergonomic analysis of virtual products and virtual work environments.

Jack software from Siemens helps you seamlessly integrate human factors and ergonomics into the planning design and validation stages of the product lifecycle. Process Simulate Human built on Siemens industry-leading Jack technology is a human modeling and simulation tool that enables you to improve the ergonomics of your product designs and to refine industrial tasks. This advanced trusted product enables you to size your human models to match worker populations.

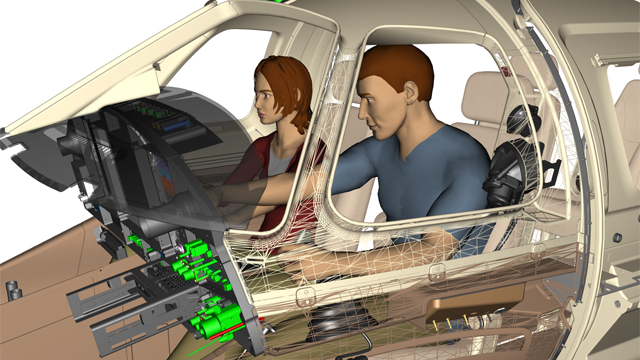

PhaseSpace Animazoo 5DT Cyberglove AVSoft UGS Jack Autodesk. 3637 Jack Manual in Details Exercise. The JACK ergonomic analysis software was used to simulate and analyze the drivers driving posture and.

Learn how you can design better manual assembly stations using our human simulation tools. Jack Manual in Details User Guide. Ergonomics research strives to make workers labor more efficient safer and more comfortable.

Rapid Upper Limb Assessment Software and Step-by-Step Training. Comprehensive tutorial for the UGS Jack software package Integrate classical ergonomics and human factor curriculum with interdisciplinary design engineering tools. Jacks Task Analysis Toolkit is a set of ten ergonomics analysis tools that help you design industrial tasks for optimal safety and productivity.

PhaseSpace Face Tracker Facial Motion Capture FT2000S Software Custom Get More Info. The software can be downloaded instantly and is valid for 12 months. An add-on to Jack 22i the Task Analysis Toolkit provides tools for.

Workplace ergonomics is the science of designing the workplace keeping in mind workers capabilities and limitations in order to reduce risk of injury and. Improve the ergonomics of your designs and the safety efficiency and comfort of your workplace environments using Jack and Jill virtual humans. Low Back Spinal Force Analysis Static Strength Prediction NIOSH Lifting Analysis Predetermined Time Analysis.

Human Vision and Virtual Reality. That means you are now able to see and analyse workers natural motions from the real workplace working on real tasks in real-time offline replay is possible as well. Jack as many of you know is our digital human simulation and modeling software.

This video shows the range of anthropometric databases and task an. A JACK-Based Ergonomic Analysis and Design of the Cockpit of Agricultural Material Handling Vehicle Abstract. Therefore six digital humans and welding torch model were built and evaluated based on the Jack software in order to improve the ergonomics of welders standing postures.

Parameterizable human models size weight gender age equipment Anthropometric databases. Ergonomic software offers a broad range of options to assist those conducting ergonomic evaluations job analyses or biomechanical analyses of specific job tasks. Jack enables you to size your human models to match worker populations as well as test your designs for multiple factors including injury risk user comfort reachability line of sight energy expenditure fatigue limits and other.

Applications can include risk factor identification training and job or workstation redesign. The goal of this program is to help engineers doing research in the field of ergonomics and workplace safety learn how software can help them perform human factors analysis virtually and thereby take. With new anthropometric databases and enhancements for seated postures and disembodied hands Jack 71 increases the speed and accuracy of a manufacturers ergonomic studies so they can make smarter decisions that result in better products.

Virtual ergonomic assessments to help improve your teams health and productivity. Jack is a human modeling and simulation tool that enables you to improve. Process Simulate Human NX Human Read more Featured customer success Costan Costan addresses market opportunities assesses employee risk and notably reduces costs using Solid Edge and Jack in Tecnomatix.

Tecnomatix Jack Human Simulation is a human modeling and simulation tool that helps you improve the ergonomics of your product designs and refine industrial tasks through. We followed the National Institute for Occupational Safety and Health NIOSH guidelines to prevent the lower back injuries that can occur while ergonomic weightlifting competition. Conduct faster and more accurate RULA assessments with the ErgoPlus Industrial ergonomics software application.

Jack is part of Siemens PLM Softwares Tecnomatrix digital manufacturing software suite. Army for dismounted soldier simulation from the US. Conceived as an ergonomic assessment and virtual human prototyping system for NASA space shuttle development it soon gathered funding from the US.

The Jack human simulation system was developed at the Center for Human Modeling and Simulation at the University of Pennsylvania in the 1980s 1990s under the direction of Professor Norman Badler. Just click on the link below fill out the form and you will receive an email with the download link and license file. The first part of article is o riented on theore tical knowledge of given pro blem.

Conduct Fast Accurate Assessments. JACK software is used to create a human model that lifts weights. Start for Free.

Tecnomatix Jack can be installed on a Microsoft Windows PC. Our built-in tools make conducting ergonomic risk assessments easier and more efficient.

Video Design Your Workstation And Processes To Restart Assembly Manufacturing Tecnomatix

A Jack Based Ergonomic Analysis And Design Of The Cockpit Of Agricultural Material Handling Vehicle Springerlink

A Jack Based Ergonomic Analysis And Design Of The Cockpit Of Agricultural Material Handling Vehicle Springerlink

Human Centered Design And Simulation Siemens Software

A Jack Based Ergonomic Analysis And Design Of The Cockpit Of Agricultural Material Handling Vehicle Springerlink

University Uses Human Modeling And Simulation In Undergraduate Research Studies Tecnomatix

A Jack Based Ergonomic Analysis And Design Of The Cockpit Of Agricultural Material Handling Vehicle Springerlink

A Jack Based Ergonomic Analysis And Design Of The Cockpit Of Agricultural Material Handling Vehicle Springerlink

University Uses Human Modeling And Simulation In Undergraduate Research Studies Tecnomatix

Human Centered Design And Simulation Siemens Software

A Jack Based Ergonomic Analysis And Design Of The Cockpit Of Agricultural Material Handling Vehicle Springerlink

University Uses Human Modeling And Simulation In Undergraduate Research Studies Tecnomatix

A Jack Based Ergonomic Analysis And Design Of The Cockpit Of Agricultural Material Handling Vehicle Springerlink

Comments

Post a Comment